BOTEK R&D Chemistry Inc. operates in compliance with AS9100 Aerospace Quality Management Systems and holds an EYDEP Class A Certification. The company is also a Ministry of Industry and Technology-approved R&D Center, and serves as a supplier of military-standard paint and coating systems for both the defense industry and general industrial applications. BOTEK R&D Chemistry Inc. is a strategic business partner of Roketsan and an approved paint supplier to BAYKAR, TUSAŞ, BMC, and ASELSAN.

"A topcoat paint compliant with TS 11590 Type 2, Class 1 and 2; based on reaction-cured epoxy resin, designed for corrosion protection of steel structures operating under severe service conditions."

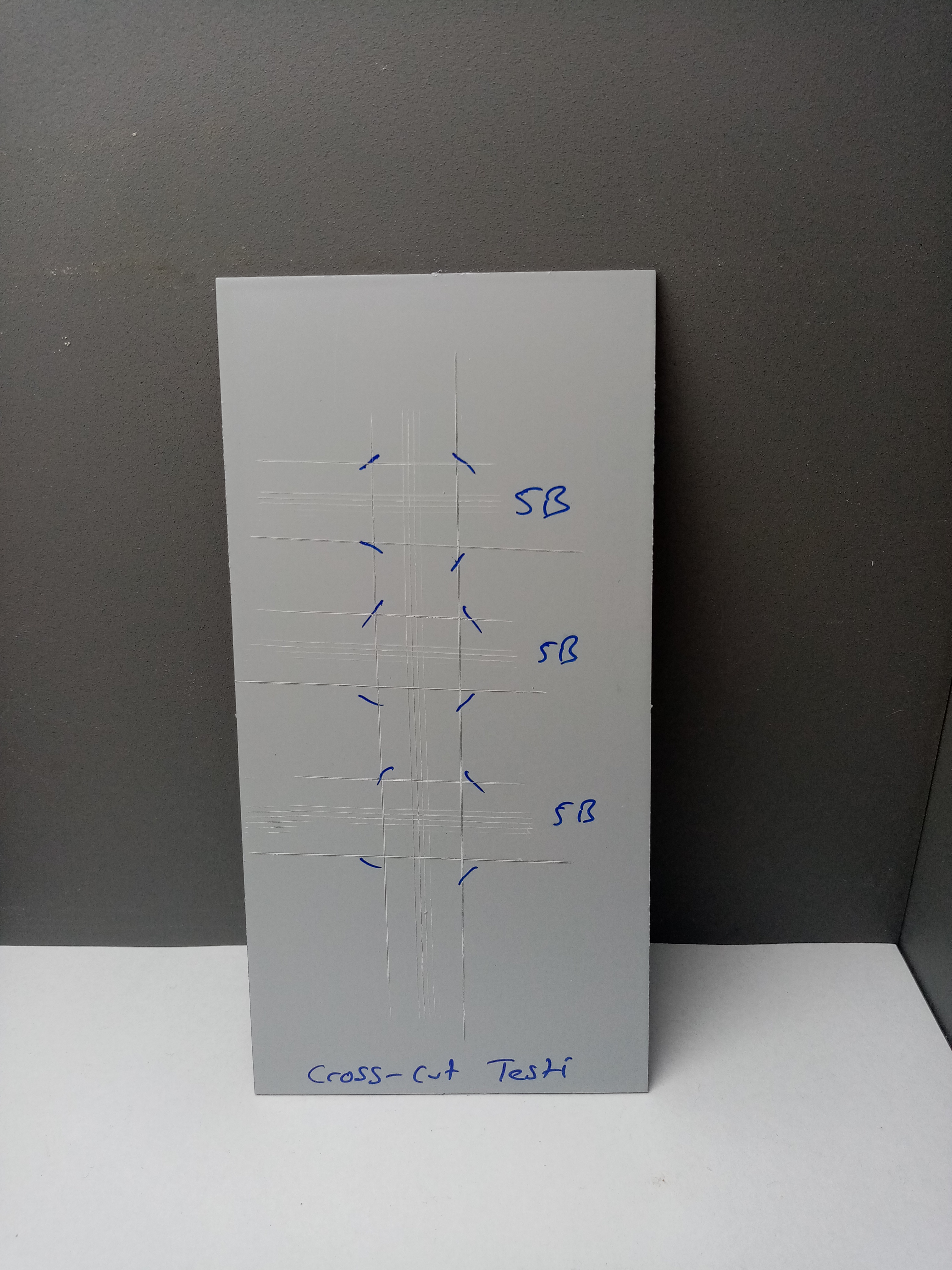

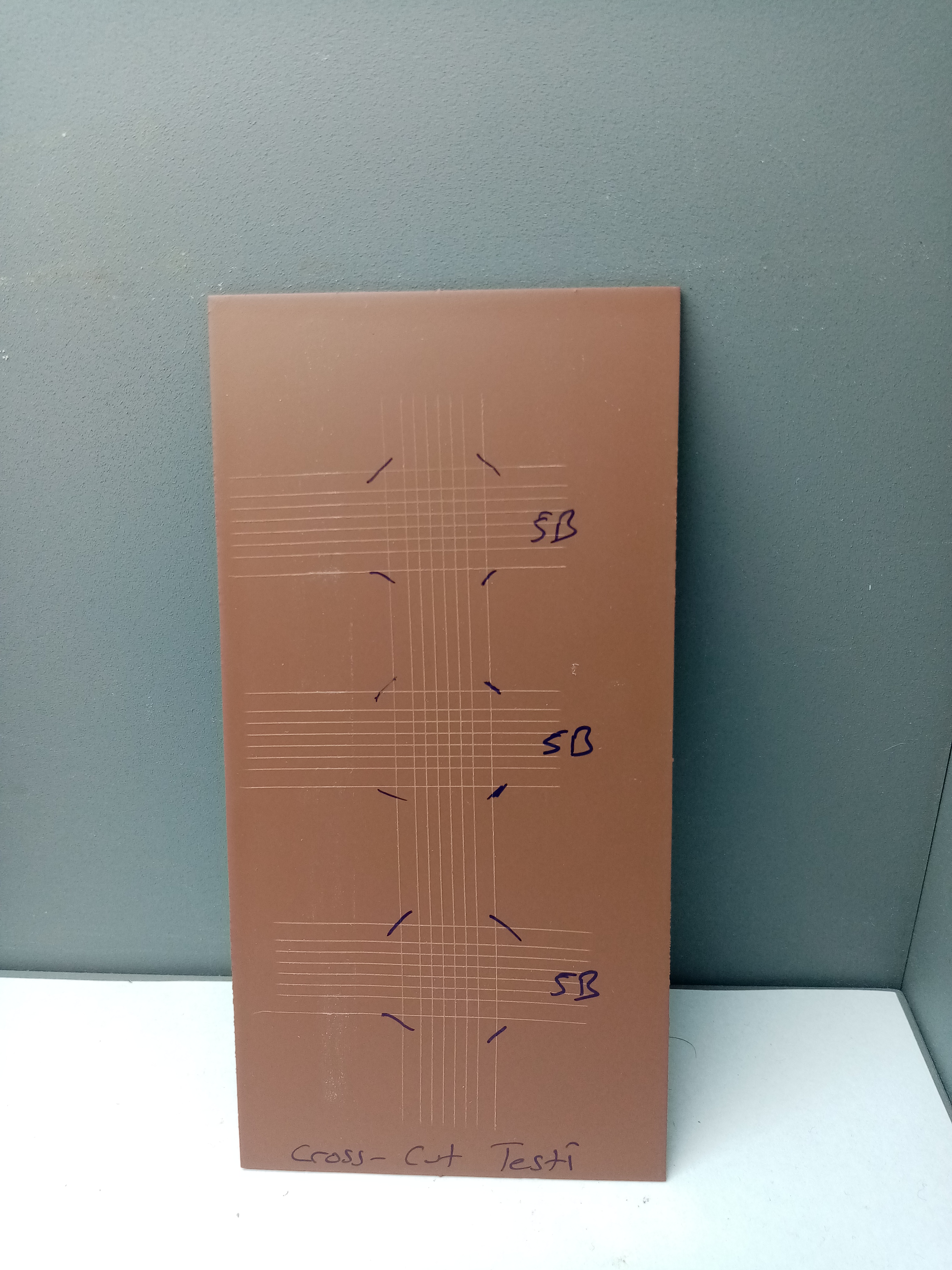

"It is a two-component, high-solids epoxy primer cured with polyamide hardener and pigmented with anticorrosive zinc phosphate. Developed for highly corrosive atmospheric environments, it forms a paint film that adheres excellently to the substrate, is flexible, and has high chemical and physical resistance. The coating allows for extended overcoating intervals without compromising performance."

"This is a two-component system comprising a Zinc-Rich Epoxy Primer and its corresponding hardener."

Two-component system consisting of Polyurethane Topcoat Paint (RAL 9010) and its corresponding Hardener

It is a two-component, high-solids epoxy high-build primer cured with a polyamide hardener and containing anticorrosive zinc phosphate pigment. It is developed for highly corrosive atmospheric environments. The product forms a paint film that adheres excellently to the substrate, is flexible, has high chemical and physical resistance, and allows for extended overcoating intervals.

The product consists of three components.

The product consists of three components: Polyurethane Topcoat FS 36320 DARK GREY + Matte Paint Hardener + Polyurethane Thinner.

It is a high-performance matte topcoat paint used on land vehicles, featuring flame-retardant and IRR (Infrared Reflective) properties. • Recommended for steel, aluminum, and composite surfaces. • It is a two-component kit. • Resistant to acids, chemicals, and environmental and atmospheric conditions. • Provides partial concealment capability against reconnaissance and surveillance activities.

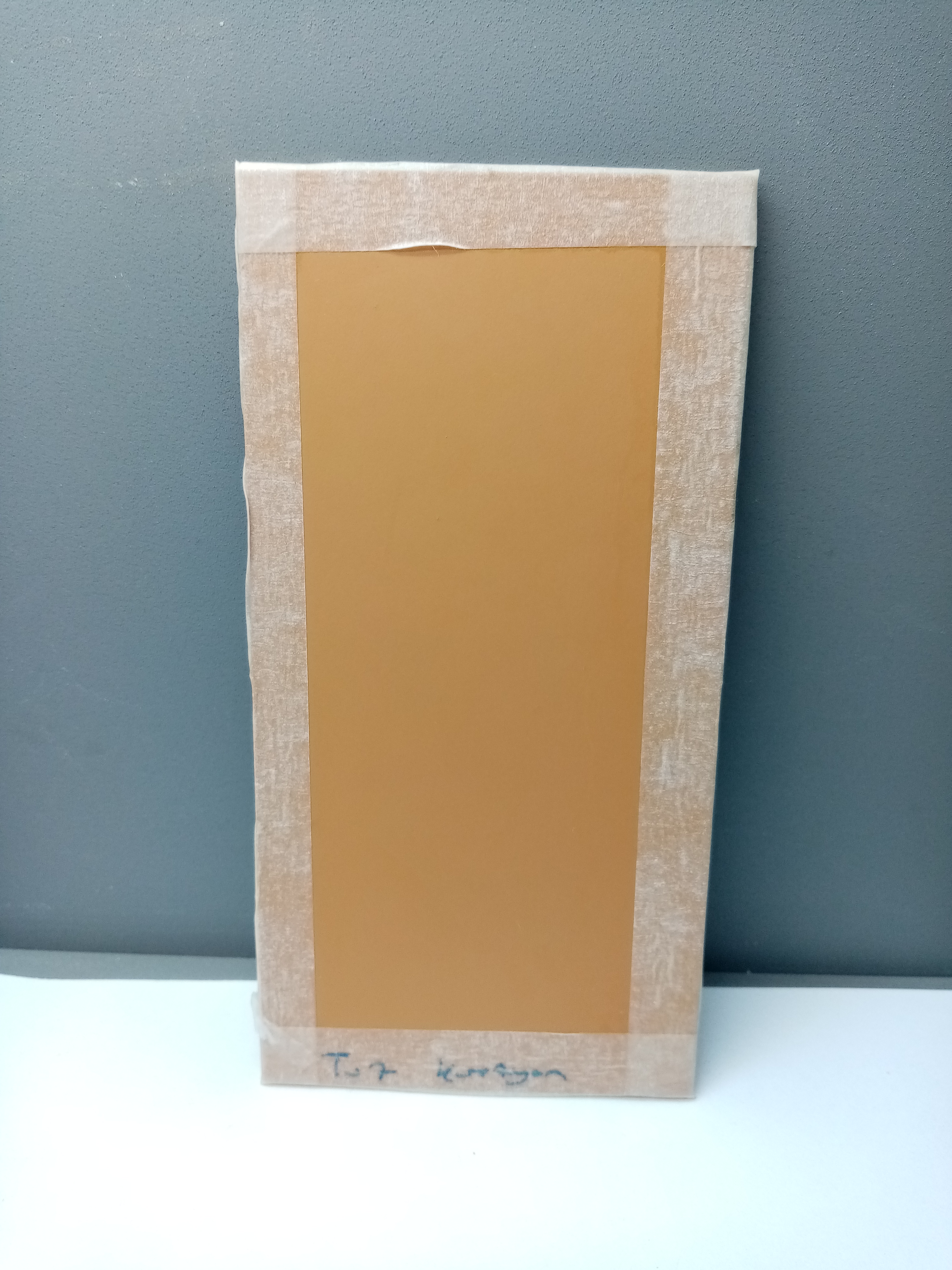

It is a high-solids, two-component, solvent-based corrosion-inhibiting epoxy primer that is chromate-free and contains zinc phosphate. Type I: “Standard Pigmented,” Class N: “Non-chromate-based corrosion inhibitors.” Provides a minimum of 2000 hours of corrosion resistance. Resistant to chemicals and solvents. Recommended for steel, aluminum, and composite surfaces. Features flame-retardant properties.

Antistatic coating is a traditional solid, carbonaceous, polyurethane coating with controlled conductivity. Used to achieve low surface conductivity on non-conductive substrates such as radomes and antennas where static charge is required. •Discharges static charge. •Resistance is 1.0 to 100 MΩ per square meter •Compatible with ALPAR Radom Primer MIL-PRF-23377 and ALPAR Radom Topcoat MIL-PRF-85285 standard products. •Excellent adhesion to composite and plastic surfaces. •Excellent liquid resistance •Compatible with all current non-electrostatic spray products •A wide range of applications can be applied •Service temperature -54°C to 177°C (-65°F to 350°F)

It has low absorbency against sunlight.

It is a high-performance topcoat paint that can reflect infrared (IR) rays. •Recommended for metal surfaces such as aluminum and steel and composite surfaces. •It is a two-component kit. •Resistant to acids, chemicals, environmental and atmospheric conditions. •Provides partial concealment against reconnaissance and surveillance activities.

Resistant to acids, chemicals, environmental and atmospheric conditions. •Recommended for metal surfaces such as aluminum and steel and composite surfaces. •Two-component kit.

.jpg)

Chromate-free (containing zinc phosphate), high solids, two-component, solvent-based corrosion inhibitor epoxy primer. Type I: ‘’Standard Pigmented’’, Class N: ‘’Non-chromate based corrosion inhibitors’’ •It shows at least 2000 hours of resistance against corrosion. •It is resistant to chemicals and solvents. •It is recommended for steel, aluminum and composite surfaces.

It is a high solids, two-component, solvent-based corrosion inhibitor epoxy primer containing strontium chromate. Type I: “Standard Pigmented”, Class C2: “Strontium chromate-based corrosion inhibitors” •It shows at least 3000 hours of resistance against corrosion. •It is resistant to chemicals and solvents. •It is recommended for aluminum and composite surfaces.

.jpg)

MIL-DTL-64159B, Type II coatings are two-component, water-based polyurethane chemical resistant coatings (CARC) for military equipment.